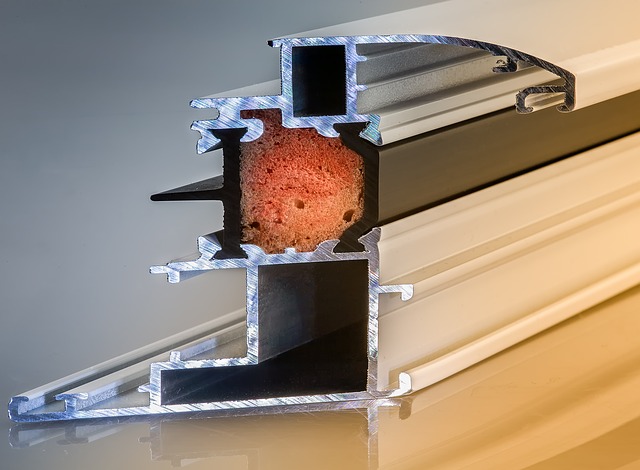

There are a number of methods to work a metal into different forms. One of the most widely used methods is extrusion. This involves pressing a workpiece into a die to obtain a material with a certain desired cross-section. Builders and suppliers prefer extrusion to other techniques because it is quicker and the output is much denser and smoother.

How Extrusion Works

The process starts with the preparation of the workpiece, which is a metal block of standard size. Depending on the desired result, the workpiece is either heated or kept at room temperature before being fed into the die. As soon as the billet is fitted inside the container, the plunger is placed on the opposite end and made ready to push the billet towards the die. The compressive force used to press the billet is enough to extrude the billet by way too low to affect the whole container.

Unlike casting, which involves smelting the metal, pouring it into a mold, and cooling to cure, the product of extrusion is virtually ready for use, unless further heat treatment is required to improve its mechanical properties. Sometimes, the output is stretched to adjust its dimension with the actual desired size and shape.

Classifying Extrusion by the Direction of Flow

Extrusion is classified according to the manner by which the billet is forced into the die or on the direction of flow. It is called direct extrusion when the billet is forced to flow in the direction of feed of punch or ram. This means that the ram moves toward the die. When it’s the die that is force into the billet, the extrusion is considered indirect.

One of the biggest issues with extrusion, especially when the billet has to be cold-worked, is that the friction building between the ram and the billet may severely affect the quality of the extrusion. To reduce friction, a special fluid is placed within the container to separate the plunger from the billet. A considerable distance will prevent the development of friction, consequently improving the quality of extrusion. This type of extrusion is called hydrostatic.

Classifying Extrusion by the Working Temperature

Extrusion can also be classified based on the working temperature. Extrusions that take place above recrystallization temperature (50-60% of the billet’s melting temperature) are known as hot extrusion. On the other hand, extrusions that take place below crystallization temperature (room temperature) is known as cold extrusion.

Some metallurgists prefer hot extrusion because it requires low force, as the billet is more fluid and free from stain hardening. However, the chemical change in the metal due to the increase in temperature within the container also increases die wear. Cold extrusion, on the other hand, is preferred by a huge array of industries because its product is known to have high mechanical properties, great surface finish, and oxidation-resistant surface.

Applications

Extrusion is primarily used in producing tubes and hollow pipes with simple and complex cross-sections. Square and round brass extrusions, for instance, make a great addition to interior accessories in homes and commercial buildings. Most windows, doors, and frames of automobiles are also made of extruded metals. Simply put, a huge fraction of metals you see in any structure are made through this metalworking process.

You can definitely save a great deal of money on extrusion. No matter the type of project you are working on, if you need freshly manufactured tubes and pipes, you better choose extruded products over cast ones. Luckily, there are suppliers like Rotax Metals that provide high-quality extrusions that are perfect for your projects.

Source:

Extrusion Process: Working, Types, Application, Advantages and Disadvantages, mech4study.com