Brass is one of the first few metals unearthed by man. Since its discovery about 3,500 years ago, brass has been used for many different purposes, primarily for making ornaments. With innovation, which had taken a long way from smelting to speltering, brass has evolved alongside copper and bronze, providing materials for making valuable items such as coins, statues, and musical instruments.

How to Obtain Brass

Brass is an alloy of copper and zinc, two well-known and widely used metals. Copper is used in many different applications, such as electrical wire cores and electronics, while zinc is primarily used for galvanization. Both metals are packed with amazing features, which is why when mixed together, the resulting metal–brass–comes with a great deal of beneficial properties as well.

There are about 60 types of brass available on the market, each containing different amounts of copper and zinc and comes with a unique set of properties. Manipulating the proportions of the two metals allow metalworkers to produce more variations of brass. This is made possible not by the alloying process alone, but also by the mechanical and electrical processes involved. Different methods produce different brasses, each with features that suit specific applications.

Categorizing Brasses

It is essential to know the different types of brass before making a purchase to ensure that the items you will buy suit your needs. Brasses are categorized according to the resulting crystal structure after the alloying process. Crystal refers to the arrangement of the atoms of zinc and copper in the alloy.

Alpha. Brasses with alpha crystals, or uniform molecular structure, belong to this category. They are usually soft and ductile with a golden hue. They can bend, blaze, and roll well. They also have high resistance to corrosion.

Alpha Beta. Also known as duplex, alpha beta brasses contain both alpha and beta crystal structures. Compared to alpha, they are harder and stronger. Working with this type of brass requires high temperature.

Beta. Brasses that belong to this category are rare, which is why consumers don’t use them. However, they contain about 45 percent zinc, making them strong and suitable for tough projects.

Uses of Brass

With brass’s amazing features, it can be used for many different applications. Here are some of them:

Musical Instruments. Resistance to corrosion, malleability, and acoustic attributes are among the properties of brass that make it perfect for manufacturing musical instruments. It can be manufactured into tubes, which can be coiled and folded to form musical instruments like trumpet, cornet, horn, and tuba.

Jewellery. A lot of jewellery pieces are created with brass clasps, slides, and enhancers. Some pieces are even made of brass alone. This is due to the metal’s golden hue and anti-corrosion properties.

Architecture. Virtually all kinds of brass are ductile and malleable. Also, their color and texture are perfect for both simple and complex architectural designs. They can be formed into wires, tubes, plates, and sheets, or engraved to make the most luxurious-looking ornaments and interior design elements.

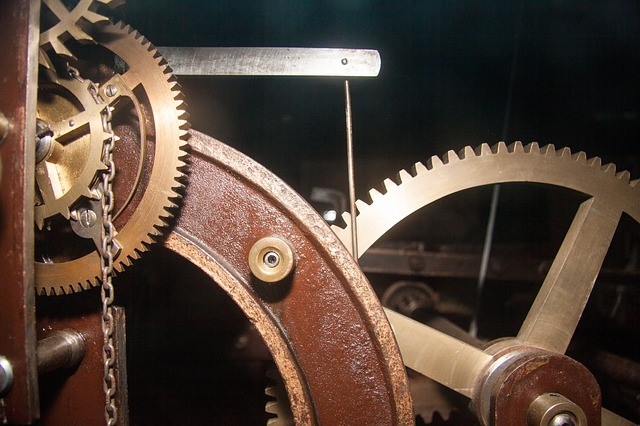

Industrial uses. Brass is very easy to work with. In spite of that, it is still durable, friction-resistant, and can tolerate extreme heat. This is why it is the material commonly used for making plumbing system parts and machine bearings.

Why Prefer Brass to Other Types of Metal?

Brass is the material of choice for many manufacturers and builders due to its numerous useful properties. Compared to zinc and bronze, brass is more malleable. It also has a high thermal expansion coefficient, lowering its melting point to 900-940 degrees Celsius. In spite of this, the metal is still easy to cast.

Because brass is made from two metals that are highly resistant to corrosion, it is expected to have the same property. However, it gets easily tarnished, yet it doesn’t affect its corrosion resistance and overall performance.

This is the reason why like copper and aluminum, brass is also recyclable. Those who are looking for an eco-friendly solution to their metalworking projects should consider using brass. Most brass products, particularly brass square tube supplies, have a faro magnetic property, which makes them easy to separate from other metals in a scrapyard. By passing brass through powerful magnets, it can be obtained and melted to produce billets, and eventually new supplies.

When looking to buy brass supplies, turn only to a reputable suppliers, such as Rotax Metals–one that has been in operation for decades. The supplier should have vast knowledge about brasses and other metals, particularly the products you are purchasing.

Sources:

Facts About Copper, Geology.com

10 Zinc Facts, ThoughtCo.com