An alloy of copper and zinc, brass is widely used in various industries. Though the generic term used is “brass,” there are more than 60 different types of it. Their properties are not the same but all brass are known for their strength, corrosion resistance, and machinability. They’re also conductive and easy to produce and not to mention, recyclable and environment-friendly.

While you can rely on all types of brass, it’s still important to know their classifications. This way, you can find the right type for the project you’re working on. One way to determine the type of brass is based on its crystal structure.

The crystal structure of brass pertains to the combination of copper and zinc that differs based on peritectic solidification. This means that the way two elements with different atomic structures come together is influenced by temperatures and content ratios.

There are three main types of crystal structure.

Alpha Brasses

This type is known for its softness and ductility since it’s mostly cold worked, bent, drawn, rolled, or brazed. It usually contains 30% zinc and 70% copper. When zinc dissolves and turns into copper, a solid solution with uniform composition occurs, forming the alpha crystal structure. This is also why it is more resistant to corrosion than brass that holds higher zinc content. Alpha brasses are mostly utilized for fasteners like wood screws and spring contacts that you can find in electrical sockets.

Alpha-Beta Brasses

Harder and stronger than the Alpha type, Alpha-Beta shares the atomic properties of pure zinc. It’s called “duplex brasses” or “hot-working brasses,” with 37% to 45% of zinc made up of alpha and beta grain structures. It also has other alloy elements like aluminum, tin, or silicon.

Because of such properties, Alpha-Beta offers lower cold ductility and resistance to dezincification corrosion. It has to be worked on at high temperatures by die-casting, extrusion, or stamping. It’s also a more affordable choice because of its high zinc content.

Beta Brasses

Beta brasses are less used than the other two types. It contains more than 45% zinc, making it the hardest and the strongest type of the three. With such structure, beta brasses must only be cast or hot worked.

Knowing the different structure will give you a better idea on what works and not depending on the needs of your project. Their applications vary, so you have to choose the type that is designed for your industry.

Applications

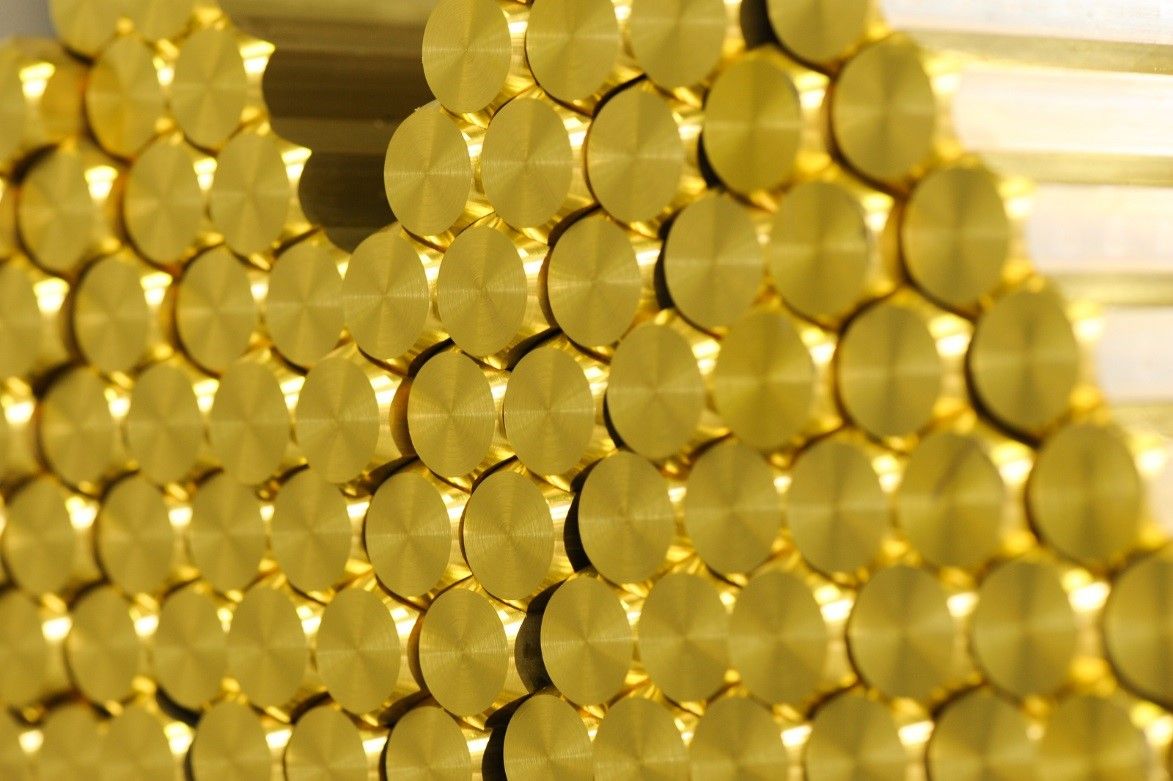

Brass comes in various forms, including bars, rods, and other shapes. That’s why many industries heavily rely on it. For instance, this metal has been used to produce musical instruments for hundreds of years. They make good sounds as long as they are designed properly.

Brass is also utilized for plumbing and other applications that involve water. They’re ideal for transporting water via pipes and fittings since they’re resistant to corrosion. The marine industry is also one of the heaviest users of brass. This metal is used in marine engine and pump parts. In fact, brass was first commercially used in building naval ships.

Moreover, brass has a non-magnetic quality, making it a good material for works that should never be affected by magnetism. Among these are clocks and watch components, as well as munitions and electrical terminals.

Listing down all applications of brass is quite impossible because it varies greatly. You can even find it in jewelry, hardware items, architectural fascias, badges, grillwork, appliances, tanks, containers, locks, and wheels, among others.

The key to navigating your way into brass sales is to know the needs of your projects and identify the differences in various types. You may also want to work with a good supplier who can guide you along the way.

Sources:

Brass Types, Thebalance.com

Brass Alloys and Their Applications,