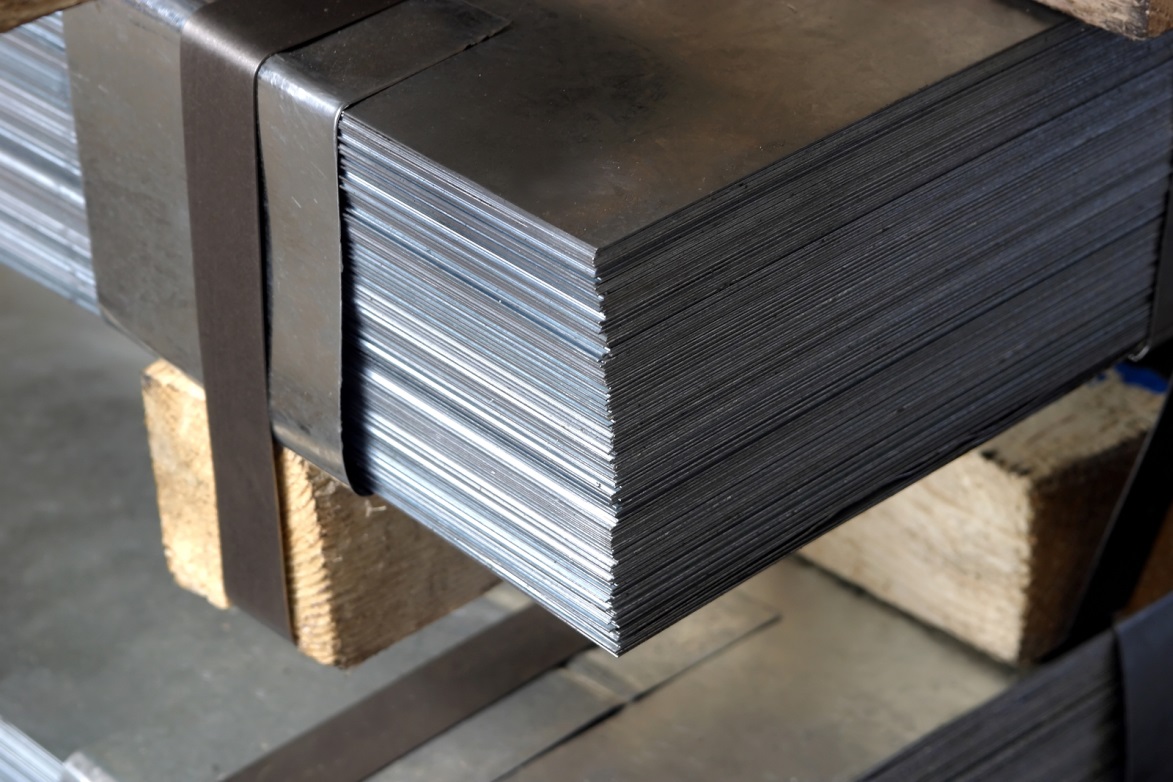

Many different types of metals can be purchased as sheets, square metal tubing, angles, and other forms. These forms each have a distinctive use that is appropriate for certain projects.

In addition to these basic forms, each metal can be further distinguished by properties such as thickness and weight. This is referred to as a gauge. The gauge of a piece of metal is assigned a number that corresponds to a certain weight or thickness. Generally, as the weight of the metal decreases, the gauge number increases.

Using the right sheet metal gauge for any product is important; however, it is not always easy. Sheet metal suppliers cannot always agree on gauge numbers, and there are some who disagree with the use of gauge numbers at all. This is because some projects require that the measurements of the material be exact.

The reason that the gauge system is disputed is because some weights might be rounded off to meet a certain gauge if they are in between sizes. This can causes errors in sensitive manufacturing jobs that can be detrimental to whole project. This disagreement between suppliers is the direct result of the importance of choosing the right gauge of metal for a project.

However, there are things that you can do to make sure that you’re getting the right weight of metal for your project. For example, if you require the use of sheet metal, you can use a sheet metal gauge to help you measure the thickness of the sheet of metal. The gauge you use will depend on the type of metal. If you need both ferrous and non-ferrous sheets, you will need a different gauge for each metal. This is because these gauges for each metal have different thicknesses associated with them.

If the metal you need is of a rare cut, size, or weight, you can ask experienced sheet metal suppliers such as Rotax Metals to create a custom size for you. While the gauge system is great for traditional weights, you can always veer away from this system if you have a specific weight in mind.

Sources:

How to Choose, Cut, and Bend Sheet Metal, Make:

Sheet Metal Wire Gauge Sizes Table Chart, Endineers Edge