People have been plying the seas for millennia now, proving that a sense of discovery is a hallmark of the human nature. Without this curiosity to know what lies beyond the shore, Columbus or Magellan would never have discovered the New World. Of course, crucial to this discovery are the ships that explorers use.

As with all technologies, as time went on, people refined the way they constructed ships to make them more cost-effective to build and to improve their seaworthiness. Towards this goal, one metal alloy proved to be breakthrough and continues to be widely used in the shipping industry: Muntz metal.

Muntz Metal 101

Despite its name, Muntz metal isn’t actually its own kind of metal; rather it’s a type of brass alloy. George Fredrick Muntz invented this alloy in 1832 in Birmingham, England by tweaking the copper and zinc content of this brass.

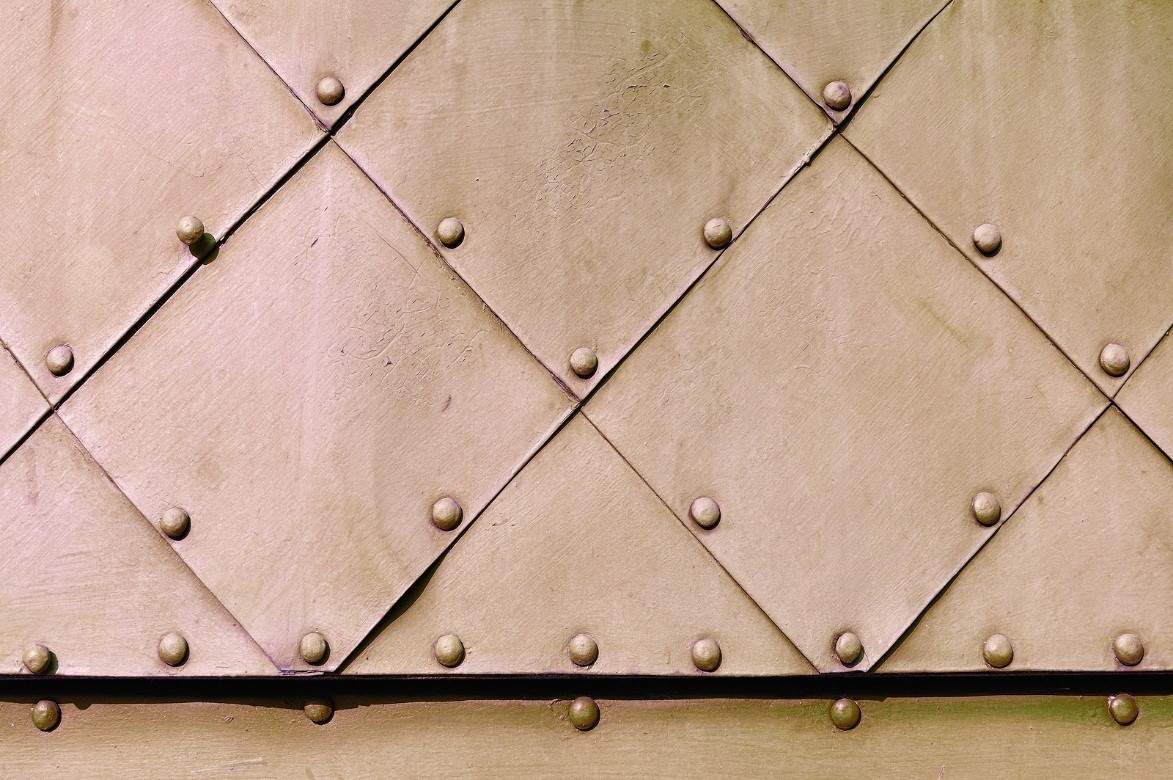

Typically, brass is made of 67% copper and 33% zinc. Muntz metal, on the other hand, is made of 60% copper and 40% zinc, with trace amounts of iron. Also unlike other brass alloys, Muntz metal employs a unique production process: the copper is first melted in a furnace, after which the zinc is added. The mixture is then placed into pans lined with clay, before being ladled into ingot molds.

This process resulted in an alloy that offers superb durability despite its lightness. More importantly, the lower copper content makes Muntz metal cheaper to produce–about two-thirds the price of standard brass–making it one of the most popular brass variants on the market.

Marine Pedigree

But why exactly is Muntz metal used in the shipping industry? The answer lies in the alloy’s chemistry: when exposed to water, the copper slowly leaches from the metal, poisoning nearby organisms. As such, it’s not surprising why Muntz metal continues to be used as lining for ship hulls–because of the leached copper, barnacles and other organisms cannot grow on the hull and slow the vessel down.

Perhaps the greatest testament to this alloy’s popularity is the fact that it was used to line the hull of the Cutty Sark, one of England’s most historic ships. And since Muntz metal can be formed into thin sheets, it’s also commonly used to line piles in pier, thanks again to its unique chemical properties.

Trusted Source

Brass sales remain brisk even to this day, including demand for Muntz metal. If you plan to use this alloy for marine purposes, make sure to source your supply from trusted manufacturers like Rotax Metals. These companies can fabricate sheets and rods suited to your specific needs and have a good track record of customer satisfaction.

Sources:

What is Muntz Metal?, wisegeek.com

A few interesting things about Muntz metal, thearticleshubonline.com