If there’s one metal that has stood the test of time and has played a crucial role in the creation of the modern world, it has to be copper. Not only is it the first metal discovered and utilized, but even as new metals are being introduced on the industrial market every five years or so, it remained a highly relevant material, and for good reasons.

Apart from possessing a number of extremely valuable properties, copper is also recyclable. Even if copper mining stops at some point in the future, there’s enough scrap copper to resupply the market with and the cycle will continue. Unfortunately, not very many people are familiar with copper. If you ask a random person on the street to name a metal they’re familiar with, they’d probably say steel or aluminum, and there’s a good explanation to that.

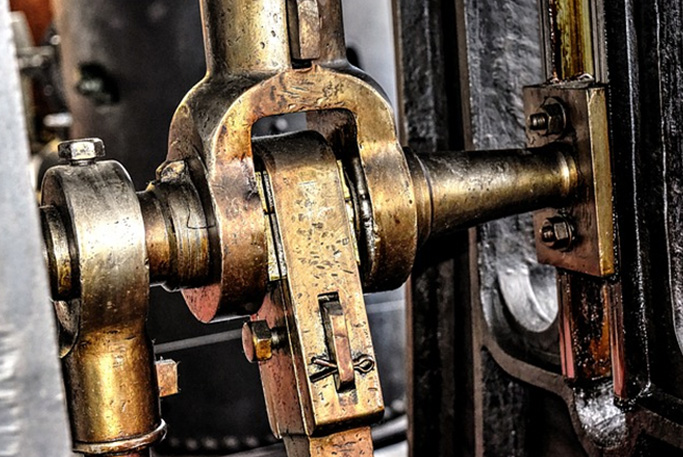

Unlike steel and aluminum, which are commonly used for building visible structures like bridges and vehicles, copper is often found inside devices and machines, making it less familiar. There’s also the fact that copper is frequently used in its alloy form, which is typically far from its original appearance. Regardless, it doesn’t change the fact that copper is an amazing metal.

Applications

To get a feel for how amazing copper really is, let’s examine its applications based on its properties and form. Especially if you are planning to start a metal supply and distribution business or your project involves the use of copper, it pays to know what this metal can do and where it is utilized for. Reputable copper and brass suppliers like Rotax Metals can give you insights that can help you make the right choices.

According to Properties

Copper’s enduring relevance is predicated by its multitudes of levered properties. Here are some of the prominent ones and their applications.

Natural Elegance

Copper has a reddish-brown color, which changes into different shades of gold or tan when combined with other metals. The resulting alloys are perfect for cutlery, sculpture, architecture, and even jewelry.

Anti-Biofouling

Barnacles, weeds, and other saltwater lifeforms cannot attach on the surface of copper or its alloys, which is why it is used for ship hulls, hydraulic systems, and offshore oil and gas platforms.

Corrosion Resistance

Unlike steel and other ferrous metals, copper does not rust. Combining it with other non-ferrous metals makes it even more corrosion-resistant. Copper makes a great material for plumbing tubes and fittings, roofing, and distillation systems.

Electrical Conductivity

Copper is extremely conductive. It’s no wonder most communication, electrical transmission and distribution, resistance welding systems are made of copper.

Ductility

Copper and its alloys are easy to work, too, but they can preserve their mechanical strength. This property is perfect for general engineering, marine, defense, and aerospace applications.

Heat Capacity

Thanks to copper’s high heat capacity, it makes up most of cryogenic, liquid gas handling, heat exchange, and combustion systems. This metal can maintain form and strength even when exposed to high temperatures for a long period of time.

Antibacterial

There’s a reason why the doorknobs and railings in buildings are typically made of copper or its alloys. Copper has a natural antimicrobial property. Its molecules produce ions that can harm certain proteins in microorganisms, leading to their demise.

According to Form

Copper and its alloys can be manufactured into virtually anything, thanks to their high malleability and machinability. However, non-customized or mass produced raw copper supplies usually come in the following shapes and forms.

-

Sheet

– Copper sheets are great for covering surfaces to add protection and aesthetic value. You can purchase a copper sheet from a local copper sheet supplier and use it on your kitchen countertop or backsplash to take advantage not just of its natural elegance but more importantly of its antimicrobial property.

-

Plate

– If you want something thicker, try a copper plate instead, although it’s more commonly used for engraving purposes. Copper plates are great for device and machine casing, too. Pure copper, however, isn’t suitable for any application requiring metal plating as it forms patina after long exposure to air and moisture.

-

Tube

–Copper is also a favorite material when making tubes and pipes. Not only is it extremely malleable, but it’s also antimicrobial, as previously discussed. Most copper tubes go to water filtration and distillation systems, food containment systems, and other structures with prohibitive sanitation requirements.

-

Bar and Rod

– Typically produced through extrusion and tensile tested, copper bars and rods are later manufactured into auto parts, medical or electrical accessories, and other precision machine components. Whether you need a copper square rod, a copper round rod, or a copper bar for your project, large suppliers like Rotax Metals have you covered.

Copper is, without a doubt, a super-metal. Even with today’s technology, there are still aspects of this metal that we haven’t fully explored, and exploited for that matter. We expect to discover more new copper-based alloys in the coming decades and it’s going to benefit a vast array of industries.