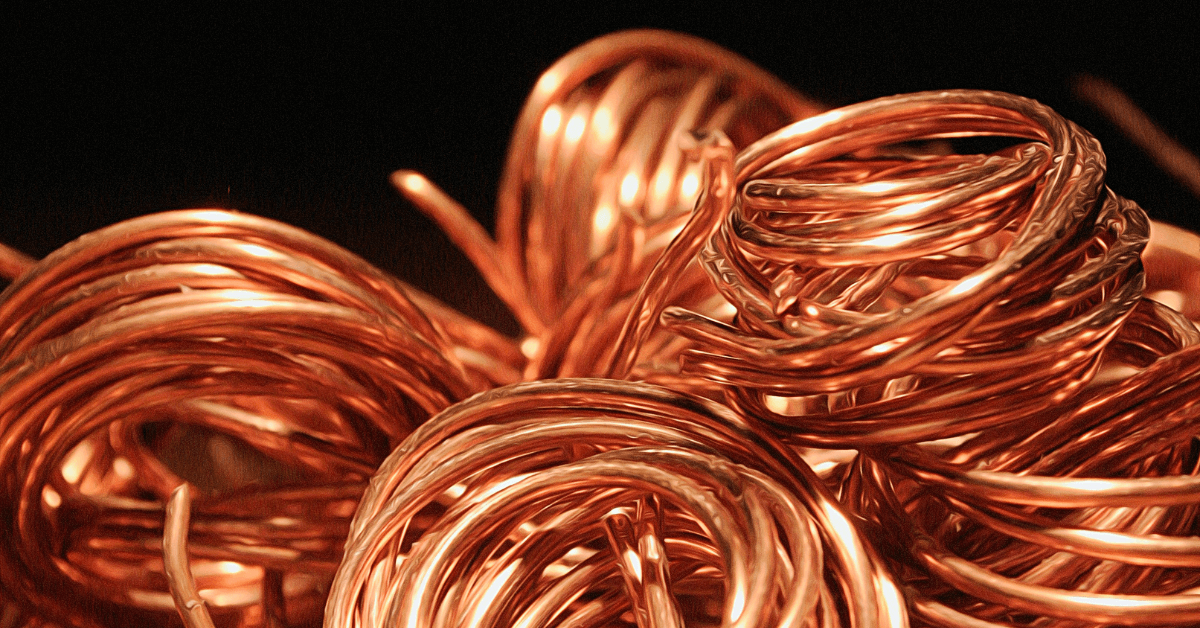

Copper is a remarkable material that plays an important role in our everyday lives. It is a naturally occurring element found in the Earth’s crust and is easily recognizable in its native copper form, appearing as a reddish-orange metal. It has been used for centuries for a variety of purposes, from creating coins and jewelry to wiring and plumbing.

Due to its excellent conductivity and resistance to corrosion, it has become a staple in the electrical industry. Additionally, copper is a crucial component in the production of renewable energy technologies such as solar panels and wind turbines. Understanding the properties and applications of copper is essential to appreciating its value and importance in modern society.

What Is Copper?

Copper is a metallic element found in pure metal form or a variety of copper compounds. It is abundant in the earth’s crust and is a key component in many industries, including construction, electronics, and transportation. One common copper compound is cuprous oxide, which is used in the production of semiconductors and as a pigment in ceramics. Overall, copper’s versatility and usefulness make it an essential element in our modern world.

History of Copper

Copper holds a significant place in human history, with the majority of the world’s copper deposits being found in Chile, followed by Peru and China. It was the first metal ever used by humans, with evidence of its use dating back to the Bronze Age over 5,000 years ago.

Copper was highly prized due to its versatility, durability, and ability to conduct heat and electricity. It was also used in the production of other metals, such as bronze, brass, and sterling silver. Copper is one of the few elements in its natural state, and its importance in human history cannot be overstated.

Application Of Copper

Copper is a versatile metal used for various purposes since ancient times. Its production has evolved over the years, and today, it ranks third in global metal consumption, behind only iron and aluminum. Copper items are ubiquitous in our lives, from electrical wiring to piping and roofing. Its properties, such as excellent corrosion resistance and thermal conductivity, make it an ideal material for a range of applications. This informative introduction provides a glimpse into the fascinating world of copper and its many uses.

Electronics

Copper plays an integral role in the rapidly advancing world of electronics. New technology and energy use are constantly being crafted, and copper wiring is often key to its functioning. Whether used to make batteries last longer or transfer electric current with precision, copper becomes vital to these technologies working correctly and efficiently. In fact, without it, further advancements may not be feasible, demonstrating how important copper remains in the successful execution of modern electronic appliances.

Architecture

Copper has been used in architecture for thousands of years due to its durability and aesthetic qualities. Copper produced from industrial machinery is often alloyed with other metals to create copper alloys with increased strength and corrosion resistance suitable for construction.

Copper’s ruddy color and malleability shape it into roofing, facades, and decorative elements. The copper patina, or verdigris, that forms over time on copper surfaces is prized for its vivid blue-green hues. Many iconic buildings feature copper in their design, demonstrating its timeless appeal and functionality in architecture.

Antimicrobial

Copper has long been valued for its antimicrobial properties. Copper occurs naturally with a relatively high melting point, allowing it to maintain its structure even after frequent touching and contact. When exposed to moisture, copper produces cuprous sulfide, a substance toxic to bacteria and other microbes. Due to this, copper alloys are often used in frequently-touched surfaces in hospitals and other healthcare facilities where reducing microbial growth is critical.

Studies have shown that copper surfaces can reduce the transfer of infection-causing germs by over 90% compared to other materials. While the antimicrobial effects of copper have been known for centuries, ongoing research continues to reveal the extent and potential of this naturally-occurring metal’s microbial-fighting power.

Why Use Copper Products For Your Project?

Copper and its alloys are essential materials for many building and manufacturing projects. Copper is highly conductive, corrosion-resistant, and durable, ideal for electrical applications, plumbing, and heat exchange systems. Copper tools and materials are also relatively inexpensive and have a steady supply, as copper is one of the most abundant minerals in the Earth’s crust. Whether you need copper wire, pipes, or sheets for your project, copper and its alloys are versatile, reliable, and practical choices for a wide range of tools, materials, and applications.

Get The Best Copper In Town At Rotax Metals!

Rotax Metals is your go-to supplier for high-quality copper and other metals in the area. We source the purest copper available and sell it to you in presentable small amounts or however much your project requires. Whether you need copper for electrical work, plumbing, or a craft project, we have you covered.

Our copper is 99.9% pure and comes in a variety of shapes and sizes. We also supply other popular metals like aluminum, steel, and brass. Stop by our warehouse for the best copper and metals in town. Contact us now and get your hands on the best metal products in town!